AUTOMATED

HAUL TRUCK

DEMUCKING SYSTEM

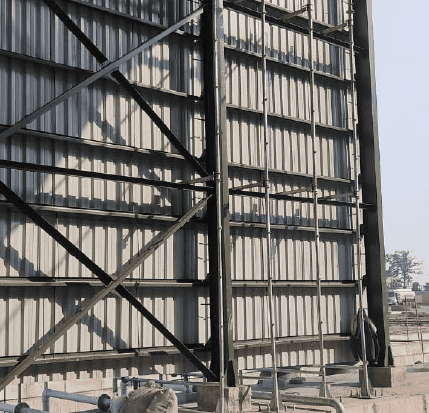

Haul Truck Wash Bay

Wash Systems Australia can design a fully automated, environmentally compliant industrial mining truck wash bay that caters to specific site requirements. The size and layout of the truck wash bay systems are completely customizable and can incorporate any number of add-ons.

Our basic supply includes a 15m long x 10m wide Haul Truck Wash Bay fitted with:

- A traffic light and sensor to start and stop the wash cycle.

- High-volume spray arches.

- Vehicle rinse arch.

- High volume undercarriage/chassis wash

- Recycling tank.

- Control panel with SCADA/PLC/remote operation and monitoring system.

Have any questions?

Download our Brochure:

Details of The Mining Truck Wash Systems

Traffic Light and Sensor

- A green light signals the vehicle to move into the wash area.

- As the vehicle moves into the Haul Truck Wash Bay, a sensor triggers the washing process.

- After a set time, the truck washing process will cease to prevent water waste.

- Water is recycled through adjacent tanks and can undergo wastewater treatment with a flocculant dosing system (optional).

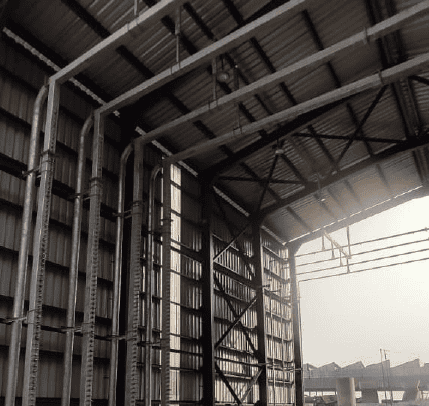

High Volume Spray Arches

- 4 high volume spray arches.

- 150 nozzles per arch.

- Nozzle diameter: 8mm.

- 4 x 38kW pumps with 6700L/min of discharge each.

Vehicle Rinse Arches

- 4 rinse arches.

- 30 nozzles per arch.

- Nozzle diameter: 3mm.

- 4 x 10kW pumps with 200L/min of discharge each.

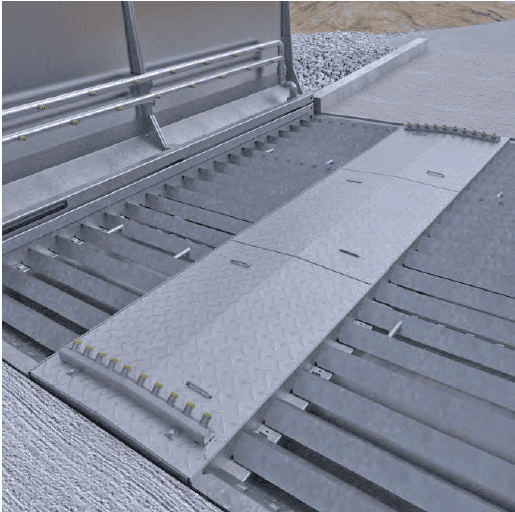

High Volume Undercarriage/Chassis Wash

- 10m long system to cover entire length of wash bay.

- 340 nozzles in total.

- Nozzle diameter: 8mm.

- 6 x 7.5 kW pumps with 2200L/min of discharge each.