Truck Washing Systems

About our truck washing systems

Wash Systems Australia has developed a strategic alliance with Frutiger Company AG to be the exclusive MobyDick partner for Australia.

Frutiger Company AG has over 30 years of experience and more than 6000 successful installations in over 72 countries.

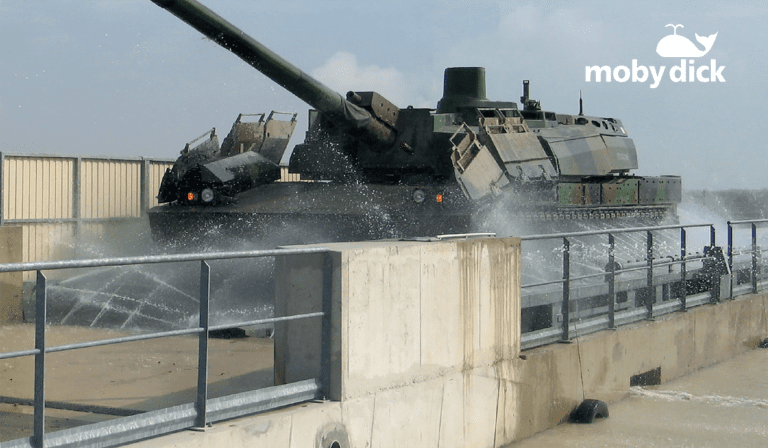

Truck Wash Bays & Wheel Wash Systems

Continuous improvement of these systems provided the next step – an automated demucking system. A concept based on recoverability, washing performance, and individual customer needs. The demucking system is one of the most modern and high-quality plant equipment and truck washing equipment systems in the world. It can be tailored to customer needs in terms of washing performance and water recycling.

The design of the wash unit and water recycling depends mainly on

the vehicle type (external dimensions, tracks or wheels, contours),

the number of vehicles to be cleaned, and the degree of soiling.

Return on investment

As the vehicle size increases the savings increase.

All water is now recycled for

future use.

People not exposed

to slips and trips in wet

surroundings.

Known results in a known

timeframe.

Our Product Range

This product range caters for the heavier duty mine vehicles from a

light truck, tracked excavator, to a large haul truck. The automated truck wash bays provide an ideal alternative for the operator to drive

through the excavator wash without leaving their vehicle or plant.

The customised closed loop recycling demucking solution is in three parts; the initial wash cycle allows for the demucking of heavily soiled light vehicles whilst the operator remains in the machine, then followed by a freshwater rinse cycle whilst traversing across a drip tray.

This customised solution is used to Demuck a plant hire fleet after returning from hire. Using this truck washing equipment, the hire company can have equipment cleaned using the automated system in minutes, not hours as previously encountered .